Exemplary Info About Can SCADA And DCS Work Together

SCADA And DCS Introduction, Types, How To Work, Advantages,

Navigating the World of Industrial Control

Ever wondered about those acronyms buzzing around industrial automation? SCADA (Supervisory Control and Data Acquisition) and DCS (Distributed Control System) might sound like robotic alphabet soup, but they're actually vital systems that keep everything from your local water treatment plant to massive oil refineries running smoothly. The big question, though, is: can these two systems actually play nice together?

1. Understanding the Roles

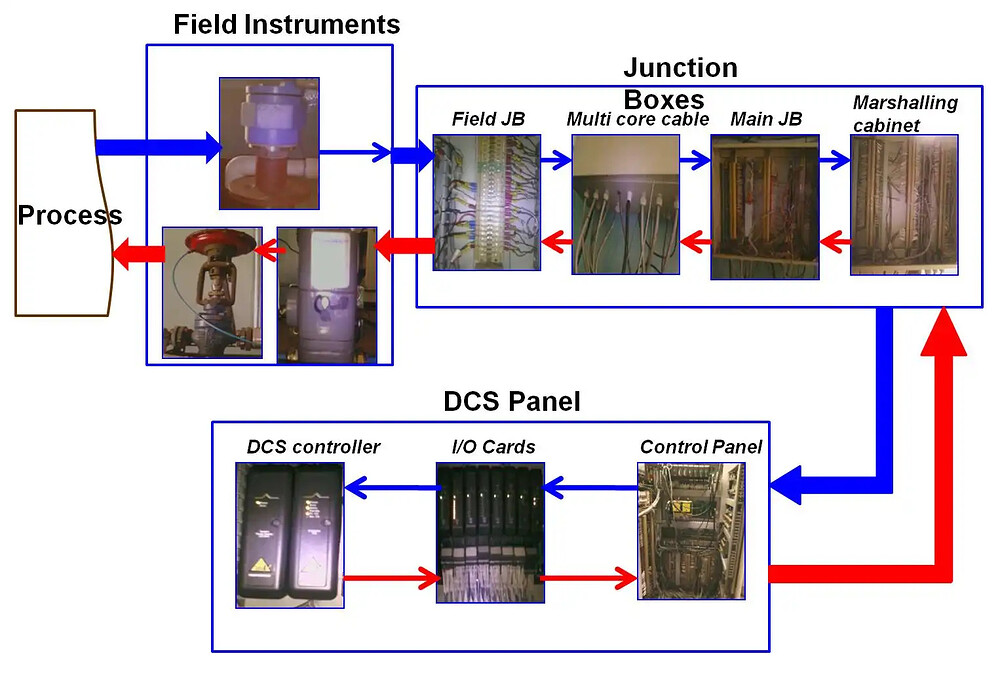

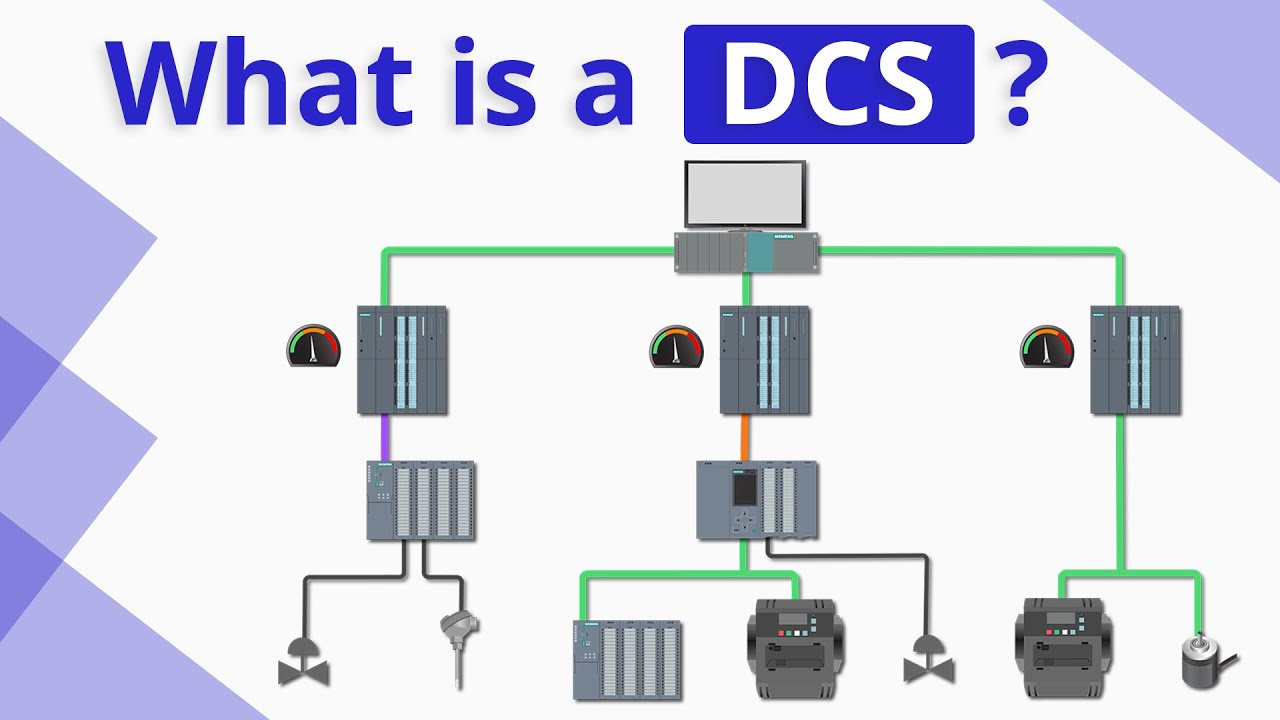

Think of DCS as the hands-on manager on the factory floor. It's designed to control processes within a specific area, like a chemical reactor or a power plant boiler. It handles the moment-to-moment operations, making sure temperatures are just right, pressures are within safe limits, and everything is humming along nicely. It's localized, focused, and really good at precise control.

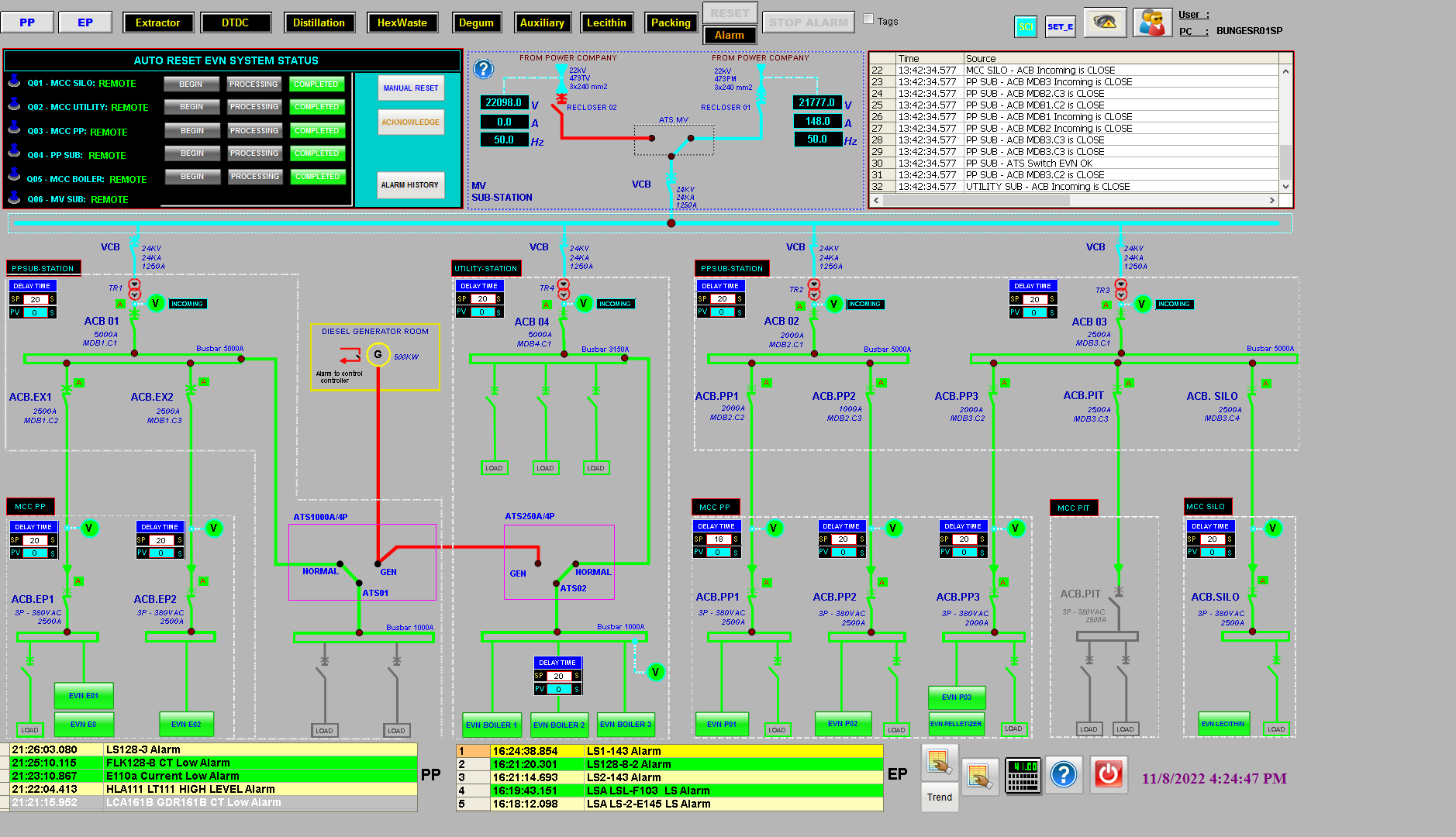

SCADA, on the other hand, is more like the regional supervisor. It oversees a wider geographical area, collecting data from multiple DCS systems (and other devices) and providing a centralized view of the entire operation. Imagine monitoring pipelines spanning hundreds of miles, or managing a network of wind turbines scattered across a landscape. Thats SCADAs domain. It's all about broad oversight, data aggregation, and remote control.

So, DCS focuses on controlling specific processes at a single site, while SCADA supervises and monitors geographically dispersed assets. This fundamental difference dictates their typical application scenarios. Picture a water treatment plant. The DCS controls the chemical mixing and filtration processes, while the SCADA system monitors water levels in reservoirs across the city and controls pumps at various locations.

Sometimes, the lines get a little blurry, which leads to confusion. But remembering their core functions helps to clear things up. DCS = tight local control. SCADA = wide area supervision. Keep that in mind, and you're halfway to understanding the interaction.

2. The Synergy

The short answer is a resounding YES! SCADA and DCS can not only work together but often do, creating a powerful and efficient control architecture. The key lies in understanding how they complement each other. The DCS handles the intricate, real-time control loops, while SCADA provides the big-picture view and remote management capabilities.

Imagine a large manufacturing plant. The DCS manages individual production lines, controlling the speed of conveyors, the temperature of ovens, and the flow of materials. The SCADA system, sitting at a higher level, monitors the overall production rate, tracks inventory levels, and allows operators to remotely start or stop production lines based on demand.

This collaborative approach provides significant benefits. The detailed process control offered by DCS ensures operational efficiency and product quality. The wide-area monitoring and remote control capabilities of SCADA improve overall system visibility, allowing for faster response to alarms and better resource management. Think about it: if a pump fails at a remote pumping station, the SCADA system alerts operators, and they can remotely activate a backup pump while dispatching a maintenance crew.

Essentially, SCADA provides the eyes and ears, while DCS provides the hands. Together, they create a robust and adaptable control system that can handle complex industrial operations. Think of it as Batman and Robin, but for industrial automation.

3. Bridging the Gap

For SCADA and DCS to work in harmony, they need to speak the same language, or at least have a translator handy. This is where communication protocols come into play. These protocols define the rules for how data is exchanged between the two systems.

Common protocols used in SCADA/DCS integration include Modbus, OPC (OLE for Process Control), and DNP3 (Distributed Network Protocol). Modbus is a widely used serial communication protocol, while OPC provides a standardized interface for accessing data from various control devices. DNP3 is specifically designed for communication in SCADA systems, particularly in the electric power industry.

Choosing the right protocol depends on the specific requirements of the application. Factors to consider include the type of data being exchanged, the distance between the systems, and the security requirements. Some protocols are better suited for high-speed, real-time communication, while others are optimized for low-bandwidth, long-distance communication.

The important thing is to ensure seamless and reliable data transfer between the SCADA and DCS systems. A well-designed communication architecture is crucial for achieving optimal performance and preventing data bottlenecks. Its like making sure everyone in a team meeting can understand each other clear communication is key to success.

4. Practical Examples

Let's delve into some real-world scenarios where this dynamic duo proves its worth. Imagine a sprawling oil and gas pipeline network. DCS units at pumping stations control the flow and pressure of the oil, while a central SCADA system monitors the entire pipeline, detecting leaks, managing pump operations, and optimizing throughput. It's a complex dance of control and supervision.

Another example is in water and wastewater treatment. DCS systems manage the chemical treatment processes, ensuring water quality standards are met. Simultaneously, SCADA monitors reservoir levels, controls pumps, and manages the distribution network, ensuring a steady supply of clean water to consumers. Without this interplay, managing such a complex system efficiently would be next to impossible.

In the manufacturing sector, the benefits are just as significant. Picture a pharmaceutical plant. DCS controls the precise mixing and blending of ingredients, ensuring product consistency. SCADA monitors production rates, tracks inventory, and alerts operators to any deviations from the norm. This integrated approach ensures both product quality and efficient operation.

These examples illustrate the versatility of SCADA/DCS integration. By combining the strengths of both systems, industries can achieve greater efficiency, reliability, and safety in their operations. It's a win-win situation for everyone involved.

5. Challenges and Considerations for Seamless Integration

While the combination of SCADA and DCS offers numerous advantages, achieving seamless integration isn't always a walk in the park. Security is a major concern, especially with the increasing threat of cyberattacks. Connecting industrial control systems to the internet exposes them to potential vulnerabilities. Implementing robust security measures, such as firewalls, intrusion detection systems, and strong authentication protocols, is crucial to protect against unauthorized access.

Another challenge is ensuring interoperability between different vendors' systems. SCADA and DCS systems are often supplied by different manufacturers, and their products may not always be compatible. Standardizing communication protocols and data formats can help to overcome this challenge. Proper planning and testing are essential to ensure that the integrated system functions correctly.

Moreover, maintaining the system over time can be complex. As technology evolves, SCADA and DCS systems need to be upgraded and maintained. This requires skilled personnel who understand both the control aspects and the IT aspects of the system. Regular training and documentation are essential to ensure that the system can be maintained effectively.

Despite these challenges, the benefits of SCADA/DCS integration far outweigh the risks. By addressing the security and interoperability concerns, industries can unlock the full potential of these powerful systems and achieve significant improvements in efficiency, reliability, and safety. Thinking proactively about these aspects can help smooth the path to success.

Hệ Thống DCS & SCADA Thiên Tân Engineering

Difference Between SCADA Vs DCS

How Deos A DCS Works? (Distributed Control Systems) Industrial

Dcs Function Block Diagram Of System For M