Simple Tips About How To Find Torque From RPM

Unlocking the Secret

1. Understanding the Relationship

Ever wondered how mechanics and engineers squeeze power out of engines? It's not just about how fast something spins (RPM), but also about how much twisting force (torque) it delivers. Think of it like this: RPM is how quickly you're pedaling your bike, while torque is how hard you're pushing on those pedals. Both are crucial to getting uphill, right? So, figuring out how these two relate is the key to understanding engine performance. This isnt some mystical art; its just a bit of physics and math working together, kind of like peanut butter and jelly. They complement each other perfectly!

The fundamental thing to remember is that horsepower (or power, in general) is directly related to both torque and RPM. Change either, and you change the power output. Picture a weightlifter. They can lift a lighter weight many times in a minute (high RPM, low torque), or a very heavy weight only once (low RPM, high torque). Both scenarios demonstrate power, just in different ways. With engines, its the same idea but with rotations and twisting forces.

Okay, so now that weve got the basic analogy sorted, lets dip our toes into the slightly more technical side. The precise connection involves a constant. Dont worry, it's not some terrifying number pulled from thin air. This constant exists to account for the units we use to measure these things (RPM in revolutions per minute, torque in pound-feet or Newton-meters, and power in horsepower or watts). Without this constant, our equation would be like trying to bake a cake without measuring cups messy and probably not very tasty.

In essence, understanding this relationship allows you to predict how an engine will perform under different conditions. High RPM with decent torque means good acceleration. Low RPM with high torque means you can tow heavy things with ease. The sweet spot, of course, is finding a balance that suits your specific needs — whether its winning a race or hauling a trailer across the country. We'll get into the actual calculation in a bit, but first, a little more background... because context is king!

The Magic Formula

2. The Equation Unveiled

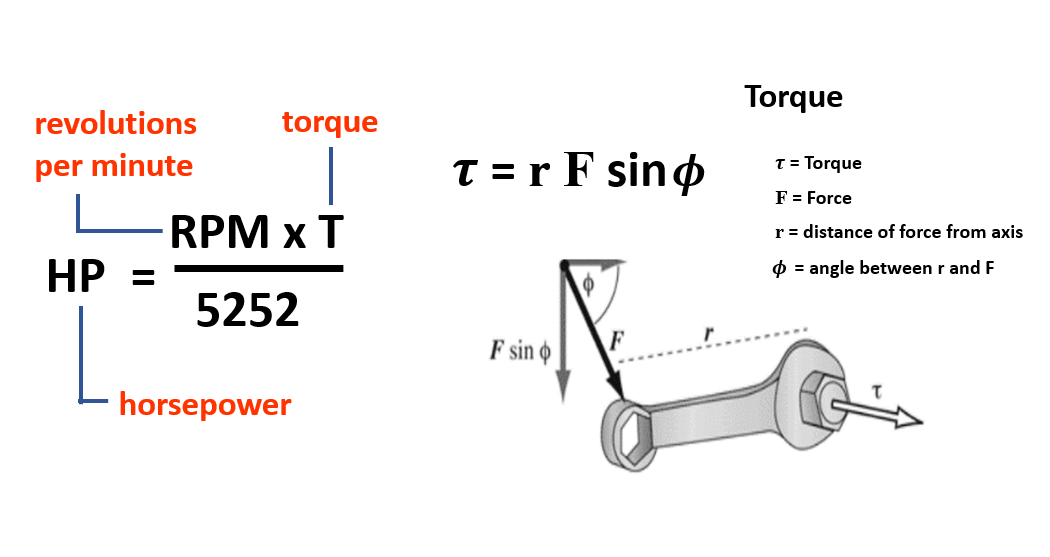

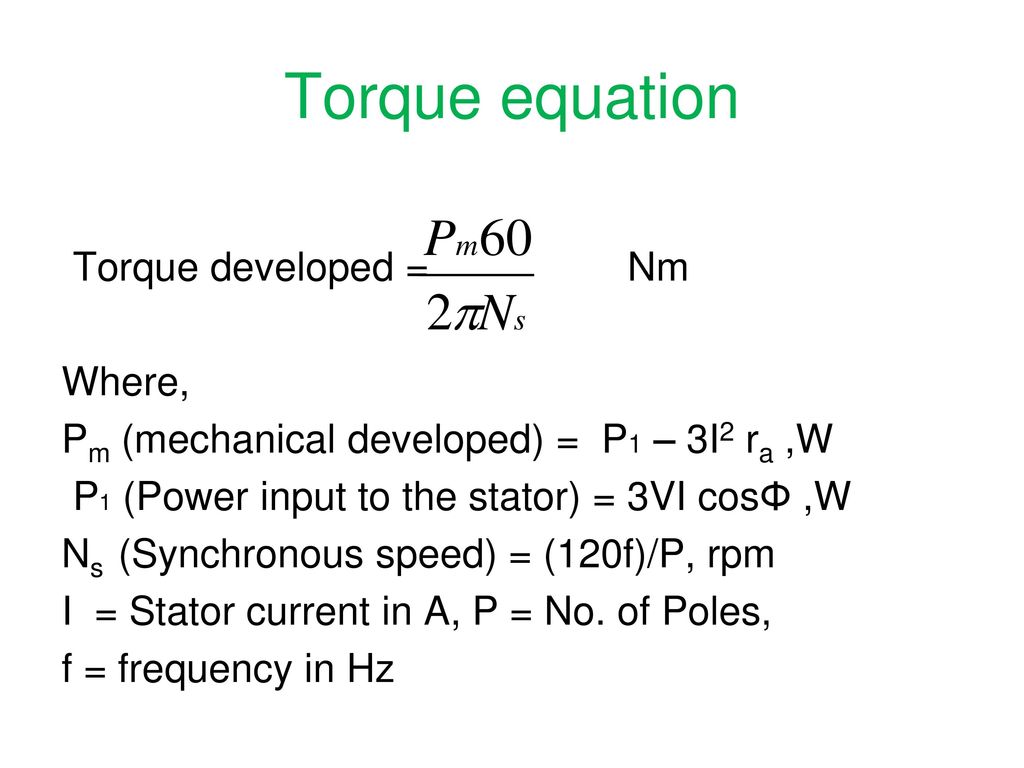

Alright, let's get down to brass tacks — the formula. It's not as scary as it looks, I promise! The equation linking torque, RPM, and horsepower is quite simple: Horsepower = (Torque x RPM) / 5252. That number, 5252, is a constant that arises from unit conversions (feet per minute, radians per revolution, etc.). Its what makes the math work out correctly. So, if you know the torque and RPM at a specific point, plugging them into this formula will give you the horsepower at that precise moment.

Now, you might be thinking, "Great, but how does this help me find torque from RPM?" Excellent question! If you know the horsepower and RPM, you can rearrange the formula to solve for torque. So, Torque = (Horsepower x 5252) / RPM. See? We just flipped things around a bit. This is particularly useful when you have access to dyno data that shows horsepower and RPM curves, but you need to understand the torque characteristics of the engine.

Let's say you're looking at an engine dyno graph and see that at 4000 RPM, the engine is producing 200 horsepower. Plugging those numbers into our formula, Torque = (200 x 5252) / 4000, gives us a torque value of approximately 262.6 pound-feet. That tells you that at 4000 RPM, that engine is exerting a twisting force of 262.6 pound-feet. Not bad, right?

But remember, this is just a snapshot at one specific RPM. Engines rarely operate at a single, constant speed. They rev up and down, so it's the entire curve of torque and horsepower across the RPM range that truly matters. Analyzing these curves will reveal where the engine's powerband lies — the range of RPMs where it produces the most usable power. This helps determine if an engine is better suited for low-end grunt or high-revving performance, or somewhere nicely in between.

Why Does This Matter? Real-World Applications

3. Putting Knowledge to Work

So, you know the formula — big deal, right? Well, understanding the relationship between torque and RPM has a ton of practical applications. Think about choosing the right engine for a vehicle. If you need a truck to tow heavy loads, you'll want an engine with high torque at low RPMs. This allows it to generate the force needed to get those loads moving without having to rev the engine to the moon.

On the other hand, if youre building a sports car for the racetrack, you might prioritize an engine with a broader powerband and higher horsepower at higher RPMs. This will give you the acceleration and top-end speed needed to win races. It's all about matching the engine's characteristics to the intended use. Imagine putting a tiny, high-revving engine designed for a motorcycle into a massive pickup truck — it wouldn't be able to pull the skin off a rice pudding!

Furthermore, understanding these concepts is crucial for engine tuning and modification. When modifying an engine, you're essentially trying to alter the torque and horsepower curves. For example, installing a turbocharger can significantly increase torque, especially at lower RPMs, making the engine feel much more responsive. Or, changing the camshaft can shift the powerband higher in the RPM range, trading low-end torque for top-end horsepower. Each modification affects these curves in specific ways, and knowing how to interpret those changes is essential for achieving the desired performance goals.

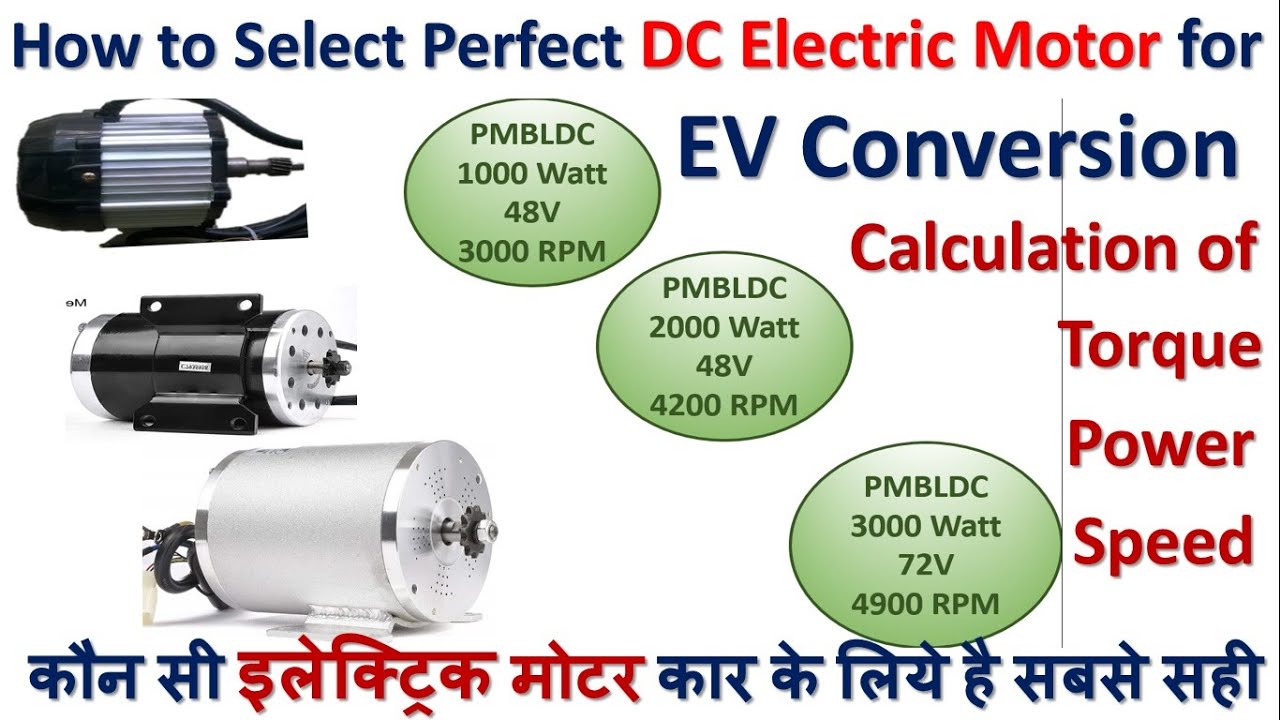

Even outside of the automotive world, the principles of torque and RPM apply. Electric motors, wind turbines, and even bicycle gears all rely on this fundamental relationship. Whether you're designing a new energy-efficient motor or choosing the right gear ratio for your bike, understanding how torque and RPM interact is key to optimizing performance. So, whether you are a professional mechanic, an engineering student, or just curious about how things work, grasping this concept is undoubtedly beneficial.

Tools of the Trade

4. Getting the Numbers

Okay, let's talk about getting those numbers! Knowing the theory is great, but actually measuring torque and RPM is where the rubber meets the road. There are a few ways to do this, depending on your needs and budget. The most common method for measuring engine torque and RPM is with a dynamometer, often called a dyno. A dyno essentially applies a load to the engine and measures the force it exerts — that's the torque. It also measures how fast the engine is spinning — the RPM.

There are different types of dynos, but they all work on the same basic principle. Some are chassis dynos, which measure the power output at the wheels of a vehicle, while others are engine dynos, which measure the power directly at the engine crankshaft. Engine dynos are generally considered more accurate because they eliminate losses in the drivetrain. These are the ones you usually see in professional tuning shops and engine development facilities.

But don't worry, you don't necessarily need a fancy dyno to get an idea of your engine's performance. Many modern vehicles have built-in sensors that provide data on engine RPM, and some even estimate torque based on other parameters. You can access this data through an OBD-II scanner — a relatively inexpensive tool that plugs into your car's diagnostic port. With the right software, you can monitor things like RPM, throttle position, and even estimated torque in real-time.

Finally, there are also specialized tools for measuring torque in specific applications. For example, torque wrenches are used to accurately tighten bolts to a specific torque value. These are essential for ensuring that components are properly secured and don't come loose under stress. So, whether you're using a high-tech dyno or a simple torque wrench, having the right tools for the job is crucial for getting accurate and reliable measurements. And remember, accurate data is the foundation for making informed decisions about engine performance and tuning!

Common Misconceptions and FAQs

5. Clearing Up the Confusion

Let's face it, all this torque and RPM talk can get a little confusing. So, let's tackle some common misconceptions and answer some frequently asked questions to clear things up. One common misconception is that high RPM always equals high power. While high RPM is necessary for high power, it's not sufficient on its own. You also need decent torque to go along with it. An engine that revs to 10,000 RPM but produces almost no torque isn't going to be very powerful.

Another misconception is that torque is only important for towing and hauling. While it's true that high torque at low RPMs is ideal for those applications, torque is also crucial for acceleration and overall responsiveness. Torque is what gets you moving off the line and helps you accelerate through the gears. Without sufficient torque, your car will feel sluggish and unresponsive, regardless of how high it can rev.

Finally, lets dispel the notion that modifying an engine to increase horsepower always improves performance. This isnt necessarily true. It all depends on how those modifications affect the entire torque and horsepower curves. Sometimes, modifications that increase peak horsepower can actually reduce torque at lower RPMs, making the car less enjoyable to drive in everyday situations. Always consider the entire powerband when making modifications, not just peak numbers.