Sensational Info About Why PPM Is Better Than PWM

PPM vs. PWM

1. The Modulation Showdown Begins

Ever feel like you're wading through alphabet soup when trying to understand electronics? I get it! Today, we're diving into the slightly less-than-thrilling, but surprisingly important, world of Pulse Position Modulation (PPM) and Pulse Width Modulation (PWM). The question we're tackling is a big one: Why might PPM be considered better than PWM in certain situations? Buckle up, because we're about to demystify these modulation methods, without getting bogged down in too much jargon. And, because life is too short to be serious all the time, I'll try to keep it light. Think of me as your friendly neighborhood modulation translator.

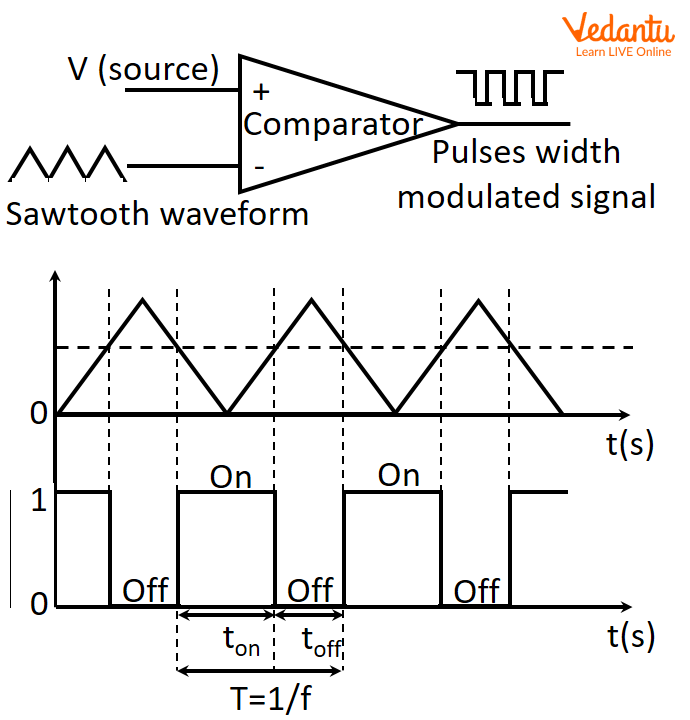

Imagine you're trying to send a message using a flashlight. You could blink it quickly or slowly (that's somewhat like PWM, where the width of the pulse changes). Or, you could blink it at specific times, marking different points in time (that's closer to PPM, where the position of the pulse changes). Both get the job done, but the advantages of each depend on the specific task at hand.

Now, before you ask "Why would I care?", consider that modulation techniques are used in everything from radio control systems (like your drone or RC car) to some types of digital communication. Understanding their strengths and weaknesses can help you make better choices in designing or troubleshooting electronic systems. Or, at the very least, impress your friends at the next geeky gathering. (Just kidding... mostly.)

So, let's get started. We won't get lost in the technical weeds. I promise to keep this as digestible as possible and avoid those headache-inducing equations that make you want to reach for the nearest nap-inducing beverage.

PWM (Pulse Width Modulation) Learn Important Terms And Concepts

Noise Immunity

2. Why PPM Thrives in Noisy Environments

One of the key advantages PPM often holds over PWM is its superior immunity to noise. Think of noise as those annoying crackling sounds you sometimes get on a radio broadcast — unwanted interference that can garble your message. In electronic systems, noise can come from various sources, like electromagnetic interference (EMI) or even poorly designed circuits.

Here's the thing: PWM relies on the width of a pulse to convey information. Noise can easily distort this width, leading to inaccuracies in the received signal. Imagine trying to measure something precisely with a slightly bent ruler; your measurements are bound to be off. PPM, on the other hand, relies on the position of the pulse. While noise can still affect the signal, it's generally harder for noise to significantly shift the timing of a pulse enough to be misinterpreted. It's like trying to change the time on a clock by waving your hands at it — more difficult than, say, smudging the minute markings on the clock face.

This inherent robustness makes PPM a great choice in environments where noise is a major concern. Think of industrial settings with lots of electrical machinery, or wireless communication systems operating over long distances. In these scenarios, PPM can provide a more reliable and accurate signal transmission, ensuring that your critical data arrives safe and sound.

To illustrate, let's take the example of controlling a model airplane. If you're flying in an area with lots of radio interference, a PPM system is more likely to accurately translate your control inputs into the plane's movements. With PWM, the noise could cause the servos to twitch or respond erratically, potentially leading to a crash (nobody wants that!).

Sự Khác Biệt Giữa PAM, PWM Và PPM

Power Efficiency

3. Can PPM Save You Some Watts?

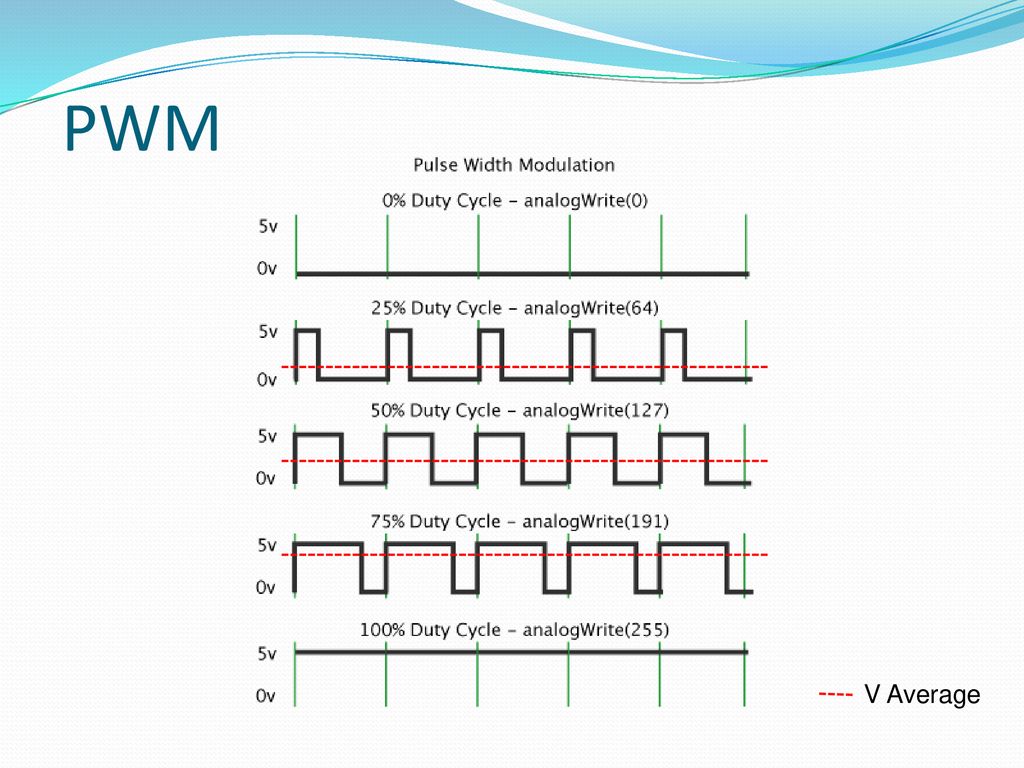

In some specific implementations, PPM can offer advantages in terms of power efficiency, although this is a nuanced point and not always a guaranteed win. The argument goes something like this: In PWM, the signal is constantly switching between high and low states. These switches consume power, particularly when driving capacitive loads. PPM, because it typically has shorter pulse durations and spends more time in a low-power state between pulses, can theoretically consume less power.

However, the actual power consumption depends heavily on the specifics of the circuit design, the switching frequency, and the type of load being driven. In many modern PWM implementations, advanced techniques are used to minimize switching losses, making the power efficiency difference between PPM and PWM negligible. It's like comparing the fuel efficiency of two cars — the make and model matter just as much as the type of engine.

Furthermore, the complexity of the PPM demodulation circuitry can sometimes offset any potential power savings at the transmission end. The receiver needs to accurately time the arrival of each pulse, which can require more sophisticated and power-hungry components. Ultimately, a careful analysis of the entire system is needed to determine whether PPM truly offers a significant power efficiency advantage in a particular application. Don't assume it's a guaranteed win.

Consider a remote control application. If the remote is only used intermittently, the power savings of PPM compared to PWM might not be substantial enough to justify the increased complexity. But in a sensor network where devices are constantly transmitting data and battery life is paramount, even a small improvement in power efficiency could be significant. The key is to weigh the trade-offs and choose the modulation method that best fits the specific requirements of your application.

Bandwidth Considerations

4. The Bandwidth Trade-Off

While PPM shines in noisy environments and potentially in power efficiency, it does come with a trade-off: bandwidth. Bandwidth, in simple terms, is the range of frequencies a signal occupies. To transmit more information quickly, you need more bandwidth. PPM generally requires more bandwidth than PWM for the same data rate.

The reason for this is that PPM encodes information in the position of the pulse. To accurately determine the position, you need to be able to resolve very small time differences. This requires faster rise and fall times of the pulses, which translates to higher frequency components in the signal. Imagine trying to pinpoint the exact moment a runner crosses the finish line — you need a high-speed camera to capture the detail.

PWM, on the other hand, encodes information in the width of the pulse. While the pulse edges still need to be reasonably sharp, the overall bandwidth requirement is typically lower than PPM. Think of it as measuring the length of a table; you don't need to be quite as precise as when timing a race.

In applications where bandwidth is a scarce resource (like wireless communication channels), this can be a significant disadvantage for PPM. It means you either need to use a wider channel to transmit the same amount of data, or you need to reduce the data rate. This is why PWM is often preferred in bandwidth-constrained applications, even if it means sacrificing some noise immunity or power efficiency.

Why Is Mppt Better Than Pwm At Arthur Snipes Blog

Complexity and Implementation

5. A Look at Implementation Nuances

PWM generally wins out in terms of simplicity of implementation. Generating and decoding PWM signals is relatively straightforward using readily available components like microcontrollers. Most microcontrollers have built-in PWM modules, making it easy to generate precise pulse width signals with minimal software overhead. Think of it as having a pre-built LEGO set ready to assemble.

PPM, however, can be a bit more challenging to implement. Generating PPM signals requires precise timing control, and decoding them requires accurate measurement of pulse positions. While microcontrollers can certainly be used for PPM, the implementation often involves more complex software or specialized hardware to achieve the necessary timing accuracy. It's like building a custom LEGO creation from scratch — more challenging, but potentially more rewarding.

This difference in complexity can have a significant impact on cost and development time. If you're working on a project with limited resources or a tight deadline, PWM's simplicity can be a major advantage. However, if you're willing to invest the time and effort to implement PPM, you can potentially reap the benefits of improved noise immunity and potentially better power efficiency (in some cases).

Consider a hobbyist building a remote control system for a robot. Using PWM, they can quickly get the system up and running with minimal effort. But if they're aiming for maximum range and reliability in a noisy environment, they might choose to tackle the challenge of implementing PPM. The choice depends on their specific goals and constraints.

So, Is PPM Really Better? The Verdict

6. It Depends!

The answer, as is often the case in engineering, is "it depends." There's no one-size-fits-all solution. PPM isn't universally "better" than PWM. Each modulation technique has its strengths and weaknesses, and the best choice depends on the specific application requirements. PPM typically triumphs in noisy environments that require robustness, while PWM usually simplifies implementation and eases bandwidth demands.

When battling noisy environments and willing to tackle more complex implementation, PPM emerges as a strong contender. On the flip side, PWM shines when simplicity is key and bandwidth is scarce. So the best choice will depend on your particular needs.

Ultimately, understanding the trade-offs between PPM and PWM is crucial for making informed design decisions. By carefully considering the noise environment, power efficiency requirements, bandwidth constraints, and implementation complexity, you can choose the modulation technique that best fits your needs and ensures optimal performance.

Hopefully, this has shed some light on the PPM vs. PWM debate. It's all about weighing the pros and cons and picking the right tool for the job. Now you can go forth and modulate with confidence!

Pulse Position Modulation Block Diagram, Circuit And Its Working

Frequently Asked Questions (FAQs)

7. Your Burning Modulation Questions, Answered!

Got a few lingering questions about PPM and PWM? Here are some frequently asked questions to clear up any remaining confusion.

Q: Can PPM and PWM be combined?A: Absolutely! Hybrid modulation schemes exist that combine the advantages of both PPM and PWM. For example, you could use PWM to encode the amplitude of a signal and PPM to encode its phase. These hybrid techniques can be more complex to implement, but they can offer superior performance in certain applications.

Q: Is PPM still used in modern applications?A: While PWM is more prevalent in many modern applications due to its simplicity, PPM is still used in niche areas where its noise immunity is a significant advantage. Think of things like certain types of telemetry systems or specialized communication links operating in harsh environments.

Q: Does the choice between PPM and PWM affect the range of a wireless communication system?A: Yes, indirectly. PPM's superior noise immunity can potentially extend the range of a wireless system, as it can tolerate more interference before the signal becomes unreadable. However, the bandwidth requirements of PPM can also limit the range, as higher bandwidth signals tend to attenuate more quickly over distance. So it's a complex interplay of factors.