First Class Tips About How Do You Test A 3 Phase Current

How To Test A 3 Phase Motor Windings With An Ohmmeter PDF Electric

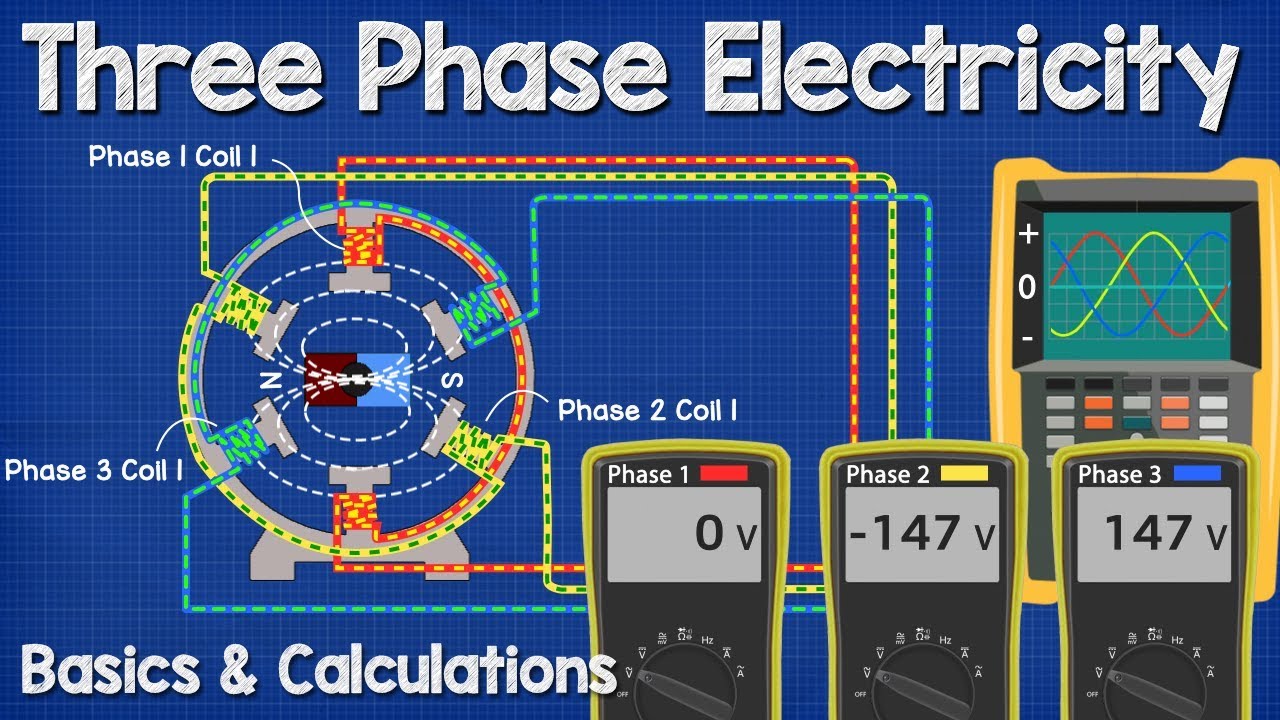

Understanding the Importance of Testing 3-Phase Current

1. Why Bother Checking Your 3-Phase System?

Alright, let's talk about 3-phase current. Now, I know what you might be thinking: "Electricity? Sounds complicated!" But trust me, it's not as daunting as it seems. Especially when you understand why keeping tabs on it is super important.

Think of your 3-phase system like a finely tuned engine. When it's running smoothly, everything hums along nicely. Businesses operate seamlessly, production lines keep moving, and your lights stay on. But if something goes wrong — say, a phase gets unbalanced — things can quickly go south. Motors can overheat, equipment can get damaged, and you might even face unexpected downtime. And nobody wants that!

Testing your 3-phase current regularly helps you catch these problems early. It's like giving your electrical system a regular check-up. You can identify potential issues before they turn into major headaches, saving you time, money, and a whole lot of stress. Plus, ensuring a balanced load helps improve energy efficiency, which is good for both your wallet and the environment. Win-win!

So, whether you're a seasoned electrician or a curious building owner, understanding how to test 3-phase current is a valuable skill. Let's dive in and see how it's done!

Safety First

2. Before You Even Think About Testing

Okay, before we get into the nitty-gritty of testing, let's have a little chat about safety. I cannot stress this enough: electricity is not something to be trifled with. It's powerful, it's invisible, and it can be downright dangerous if you don't know what you're doing.

The most important thing is to ensure that the power is completely OFF before you start poking around with any testing equipment. I'm talking about flipping the breaker, pulling the fuse — whatever it takes to completely isolate the circuit you're working on. Double-check it with a reliable voltage tester before you even think about touching anything.

Also, wear appropriate personal protective equipment (PPE). At a minimum, you should have insulated gloves and safety glasses. If you're working in a potentially hazardous environment, consider wearing a face shield and flame-resistant clothing.

And finally, if you're not comfortable working with electricity, don't! There's no shame in calling a qualified electrician. It's always better to be safe than sorry, especially when dealing with something that can be as unforgiving as electricity. Seriously, your well-being is worth more than any DIY project. Remember, stay safe, stay alive!

Essential Tools for Testing 3-Phase Current

3. Gearing Up for the Job

Alright, now that we've covered the safety essentials, let's talk about the tools you'll need to get the job done. You can't test 3-phase current with just your bare hands (please don't try!). You'll need a few specialized instruments to get accurate readings and ensure everything is running smoothly.

First and foremost, you'll need a multimeter. This versatile device can measure voltage, current, resistance, and other electrical parameters. Make sure you have a multimeter that's rated for the voltage levels you'll be testing. A good clamp meter is also incredibly useful. Instead of having to physically connect the meter to the circuit, you can simply clamp it around a wire to measure the current flowing through it.

Another tool you might find handy is a phase sequence indicator. This device helps you determine the order in which the phases are rotating. This is crucial for ensuring that motors and other equipment are running in the correct direction. Its like checking if your car is in forward or reverse before you hit the gas, important stuff!

Finally, don't forget the small but essential tools: insulated screwdrivers, wire strippers, and a reliable flashlight. These will make your life a lot easier when you're working inside electrical panels and other tight spaces. Having the right tools not only makes the job easier but also safer, so invest in quality equipment.

Can You Test A 3 Phase RCD ? HOW ??? YouTube

Step-by-Step Guide to Testing 3-Phase Current

4. Let's Get Down to Business

Okay, with your safety gear on and your tools at the ready, let's get into the actual testing process. Remember, safety first! Make sure the power is off before you start fiddling with anything.

First, grab your multimeter and set it to measure AC voltage. Then, carefully connect the probes to each pair of phases (L1-L2, L2-L3, and L3-L1). This will give you the line-to-line voltage. Record each reading. They should be roughly equal, indicating a balanced voltage supply. If there's a significant difference between the readings, it could indicate a problem with one of the phases.

Next, use your clamp meter to measure the current flowing through each phase. Clamp the meter around each conductor individually and record the current reading. Again, the readings should be roughly equal. A significant difference in current could indicate an unbalanced load or a fault in one of the phases.

Finally, use your phase sequence indicator to verify the phase rotation. Connect the indicator to the three phases and observe the direction of the indicator. This will tell you if the phases are rotating in the correct order. If the rotation is incorrect, you may need to swap two of the phases to correct it. Just remember to kill the power before you start swapping anything! Keep detailed notes of every reading you take, this information will be vital in the event of troubleshooting later.

How To Check 3 Phase Motor Winding With Test Lamp

Analyzing Your Results and Troubleshooting Common Issues

5. Deciphering the Data

So, you've taken your measurements and recorded your data. Now what? Well, it's time to put on your detective hat and analyze the results. Look for any significant deviations from the expected values. Are the voltages balanced? Are the currents balanced? Is the phase rotation correct?

If you find an unbalanced voltage, it could be due to a number of factors. It could be a problem with the utility company's supply, a loose connection somewhere in your system, or a faulty transformer. An unbalanced current could indicate an overloaded circuit, a short circuit, or a motor with a winding fault.

If you suspect a problem, don't try to fix it yourself unless you're a qualified electrician. Electrical troubleshooting can be tricky, and it's easy to make things worse if you don't know what you're doing. Call a professional and let them take a look. They have the tools and expertise to diagnose and repair the problem safely and effectively.

Remember, prevention is always better than cure. Regular testing and maintenance can help you catch problems early and prevent them from escalating into major headaches. So, make it a habit to check your 3-phase system periodically. It's a small investment that can pay off big time in the long run. And if everything looks good, then great! You can pat yourself on the back and enjoy the peace of mind knowing that your electrical system is humming along smoothly.

FAQ

6. Answers to Your Burning Questions

Here are some common questions people have about testing 3-phase current:

Q: How often should I test my 3-phase system?A: It depends on the application and the environment. In general, it's a good idea to test your system at least once a year. However, if you're operating in a harsh environment or if you're experiencing frequent electrical problems, you may need to test it more often.

Q: Can I test 3-phase current myself, or do I need to hire an electrician?A: If you're comfortable working with electricity and you have the necessary tools and knowledge, you can test 3-phase current yourself. However, if you're not comfortable, it's always best to hire a qualified electrician. Safety should always be your top priority.

Q: What are the consequences of not testing my 3-phase system regularly?A: Neglecting regular testing can lead to a variety of problems, including equipment damage, downtime, increased energy costs, and even electrical fires. It's a small investment that can save you a lot of headaches and money in the long run.

Q: What should I do if I find an unbalanced load?A: An unbalanced load means that one or more of your phases are carrying more current than the others. This can cause overheating and damage to equipment. You should investigate the cause of the imbalance and take steps to correct it. This might involve redistributing the load across the phases or repairing faulty equipment.