Who Else Wants Info About What Is An ESB Cable

Decoding the ESB Cable

1. What exactly is an ESB Cable, anyway?

Alright, let's unravel this mystery: an ESB cable, which expands to an Electric Submersible Borehole cable, is a specialized power cable. Think of it as the unsung hero working deep beneath the surface, primarily in oil and gas wells. Its primary role is to deliver power to the submersible pump, which lifts fluids to the surface. Without this workhorse, accessing those valuable resources would be a real uphill battle, or rather, a downhill nightmare! ESB cables aren't your everyday extension cords; they're built to withstand incredibly harsh environments.

Unlike the regular cables snaking behind your TV, these bad boys are designed to handle immense pressure, scorching temperatures, and corrosive chemicals. Imagine working in a sauna while being squeezed by a giant and splashed with acid — not exactly a picnic, right? That's the kind of environment these cables face day in and day out. So, robust construction is absolutely crucial to ensure continuous and reliable power delivery.

The design incorporates several layers of protection, starting with the conductor itself. This is usually made from copper or aluminum, chosen for their excellent conductivity. Next, you have insulation to prevent electrical shorts, and then layers of jacketing to protect against physical damage and chemical attack. All of this is carefully assembled to ensure the cable can survive the extreme conditions it encounters downhole. Its a bit like a submarine designed to withstand the crushing depths of the ocean.

In short, the ESB cable is the lifeline to the pump, and a well-designed, properly installed cable means the difference between a productive well and a costly shutdown. So, next time you hear about oil and gas extraction, remember the unsung hero deep below, powering the operation — the ESB cable.

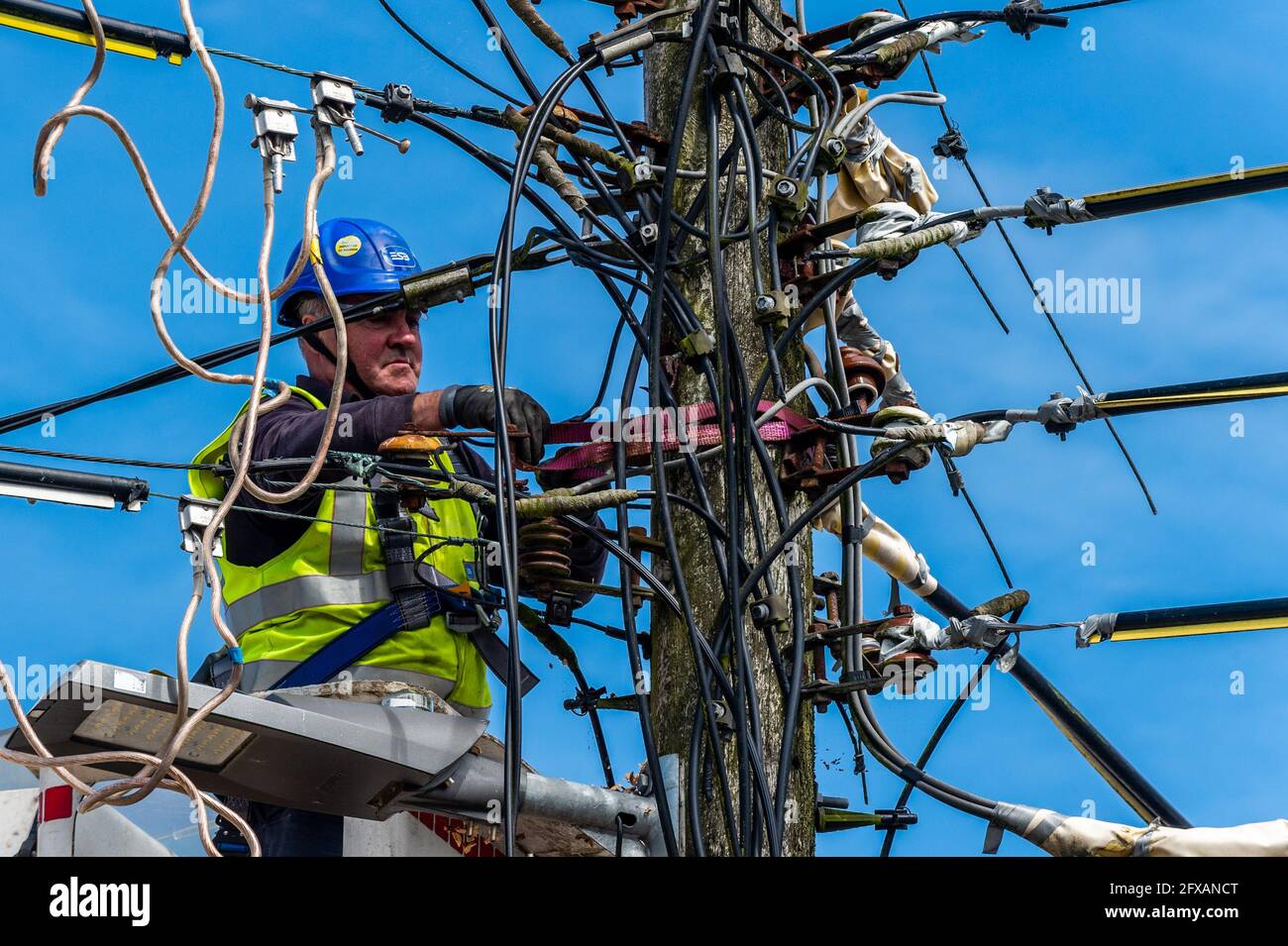

ESB Networks, Ireland, Repairing Downed Electricity Cables In

Why ESB Cables are Different Breed?

2. The Unique Demands Placed on ESB Cables

So, what sets an ESB cable apart from, say, the cable that charges your phone? The answer lies in the extreme conditions they have to endure. These aren't just your run-of-the-mill, pop-down-to-the-shops cables. We are talking about environments where high pressure, high temperatures, and corrosive chemicals are the daily norm.

Lets break down some key differences. First, the temperature. Downhole temperatures can soar to well over boiling point, so the insulation material used in an ESB cable needs to be able to withstand these scorching conditions without melting or degrading. Standard PVC insulation simply wouldnt cut it. Instead, materials like EPDM rubber or polypropylene are commonly used.

Then there's the pressure. At significant depths, the pressure can be immense, enough to crush lesser cables. ESB cables are designed with specific constructions and materials to resist this crushing force, maintaining their integrity and ensuring power continues to flow. Imagine trying to squeeze a garden hose until it bursts — ESB cables are built to avoid that scenario.

Finally, the chemicals. Crude oil, natural gas, and other substances found downhole can be highly corrosive. ESB cables are designed with protective jackets that resist these chemicals, preventing them from eating away at the cable and causing failures. Materials like lead or specialized polymers are often used to provide this chemical resistance. So, when you think of an ESB cable, think of a heavily armored warrior ready to face the harshest battlefields.

خرید YCB301C400 Yokogawa ESB Bus Cable

Material Matters

3. The Anatomy of a Robust ESB Cable

Lets dive a bit deeper into the materials that make up an ESB cable. It's not just about slapping some wires together and hoping for the best! A well-designed ESB cable is a carefully engineered product, with each component selected for its specific properties and ability to withstand the rigors of the downhole environment.

The conductor is usually made from copper or aluminum. Copper offers excellent conductivity and is relatively resistant to corrosion. Aluminum is lighter and less expensive but requires a larger cross-sectional area to achieve the same conductivity. The choice depends on the specific application and the trade-off between cost and performance.

Next, we have the insulation, which is crucial for preventing electrical shorts. Common insulation materials include EPDM rubber, polypropylene, and fluoropolymers like PFA. These materials are chosen for their ability to withstand high temperatures, resist chemical attack, and maintain their electrical insulating properties under pressure. Think of it like the protective skin around the wires, keeping them safe and sound.

Finally, we have the jacket, which provides physical protection and chemical resistance. Materials like lead, polyethylene, and specialized polymers are used for the jacket. Lead provides excellent chemical resistance but is heavy and can be environmentally problematic. Polyethylene is lighter and more environmentally friendly but may not be suitable for all chemical environments. The specific choice of jacketing material depends on the chemicals present in the well.

Each component of an ESB cable plays a crucial role in its overall performance and reliability. The materials are carefully selected and combined to create a robust, long-lasting product that can withstand the extreme conditions of the downhole environment.

Yokogawa YCB301 ESB Bus Cable

Installation and Maintenance

4. Best Practices for ESB Cable Longevity

Even the toughest ESB cable needs a little love and attention to ensure it keeps delivering power reliably. Proper installation and regular maintenance are crucial for maximizing the cable's lifespan and preventing costly downtime. Lets explore some best practices.

Installation is where it all begins. The cable needs to be handled carefully to avoid damage during installation. Bending radii should be strictly observed to prevent kinking or crushing the cable. Proper splicing techniques are also essential to ensure a reliable electrical connection. Think of it as carefully planting a tree to ensure it grows strong and healthy.

Regular monitoring is also key. Checking the cable for signs of wear or damage, such as cuts, abrasions, or chemical attack, can help identify potential problems before they lead to a failure. Electrical testing, such as insulation resistance testing, can also help detect degradation of the insulation material. It's like giving your car a regular check-up to catch any problems before they become major headaches.

If damage is detected, prompt repairs are essential. Minor damage can often be repaired with specialized repair kits. However, more severe damage may require replacing the entire cable section. Ignoring damage can lead to further degradation and eventual failure, resulting in costly downtime and lost production. Remember, a stitch in time saves nine!

Effective installation and maintenance practices can significantly extend the life of an ESB cable and ensure reliable power delivery to the submersible pump. By following these guidelines, you can avoid costly downtime and keep your oil and gas wells pumping smoothly.

SON ESB020B Mains Cable Extension Euro Plug Socket SW 2.0 M

Future Trends in ESB Cable Technology

5. What's Next for Downhole Power Delivery?

The world of ESB cables isn't standing still! As the oil and gas industry evolves, so too does the technology behind these critical components. Let's take a peek into some of the emerging trends shaping the future of ESB cable technology.

One key trend is the development of more advanced materials. Researchers are constantly exploring new polymers and composites that offer improved temperature resistance, chemical resistance, and mechanical strength. These materials will enable ESB cables to operate in even more extreme environments and last even longer.

Another trend is the integration of sensors and monitoring systems. Imagine an ESB cable that can continuously monitor its own health, detecting signs of wear or damage before they lead to a failure. This would enable proactive maintenance and prevent costly downtime. These smart cables could provide valuable data for optimizing well performance.

Finally, there's a growing focus on sustainability. The industry is looking for more environmentally friendly materials and manufacturing processes for ESB cables. This includes reducing the use of harmful chemicals and developing recyclable or biodegradable materials. Its all about reducing the environmental footprint while maintaining high performance.

The future of ESB cable technology is bright. With ongoing research and development, we can expect to see even more robust, reliable, and sustainable cables that will continue to play a crucial role in the oil and gas industry.

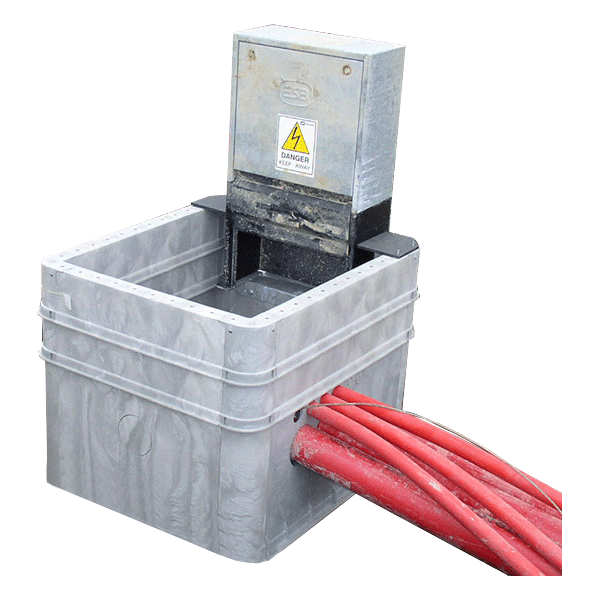

RadBox™ ESB VC2 MiniPillar Buried Networks Infrastructure Radius CTS

FAQ About ESB Cables

6. Your Burning Questions Answered

Still scratching your head about ESB cables? Lets tackle some frequently asked questions.

Q: What happens if an ESB cable fails?

A: If an ESB cable fails, the submersible pump stops working, and the wells production comes to a halt. This can lead to significant downtime and lost revenue. Repairing or replacing the cable is essential to restore production.

Q: How long do ESB cables typically last?

A: The lifespan of an ESB cable can vary depending on the operating conditions, the quality of the cable, and the effectiveness of the installation and maintenance practices. Generally, a well-maintained cable can last several years.

Q: Are there different types of ESB cables for different applications?

A: Absolutely! ESB cables are available in a variety of designs and materials to suit different well conditions. Factors like temperature, pressure, chemical exposure, and well depth all influence the selection of the appropriate cable.

Q: Can ESB cables be repaired?

A: Yes, minor damage to ESB cables can often be repaired using specialized repair kits. However, more severe damage may require replacing the entire cable section.