Spectacular Info About Which Is Better SCR Or IGBT

IGBT Vs MOSFET 5 Important Differences Between And

SCR vs. IGBT

1. Understanding the Contenders

Alright, let's get down to business. You're probably here because you're wrestling with a decision: SCR or IGBT? Which one is the superior champion for your specific power electronics needs? The answer, as always, is delightfully complicated and depends entirely on what you're trying to accomplish. Think of it like choosing between a sledgehammer and a scalpel. Both can be incredibly useful, but wildly inappropriate if you pick the wrong one for the job. So, let's dive into the key differences and see where each shines.

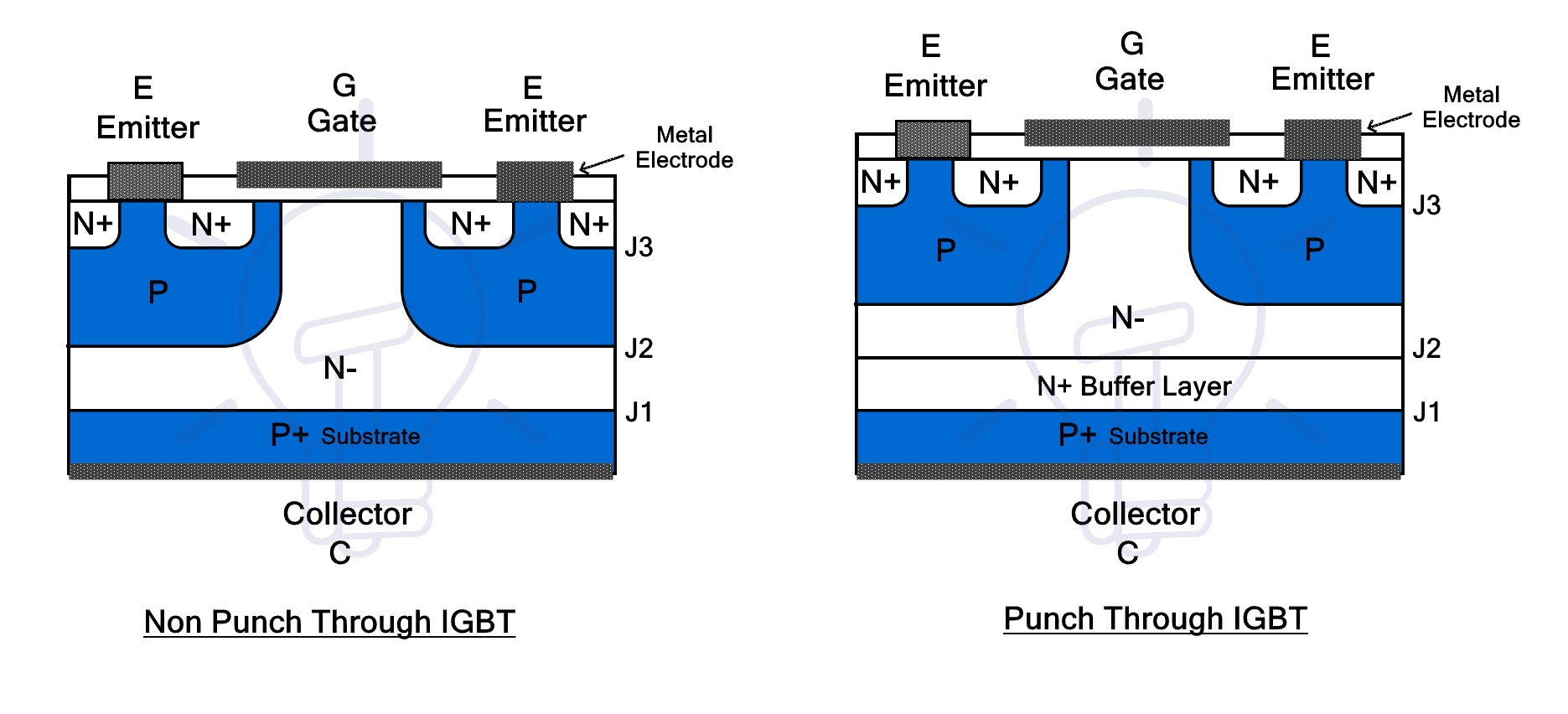

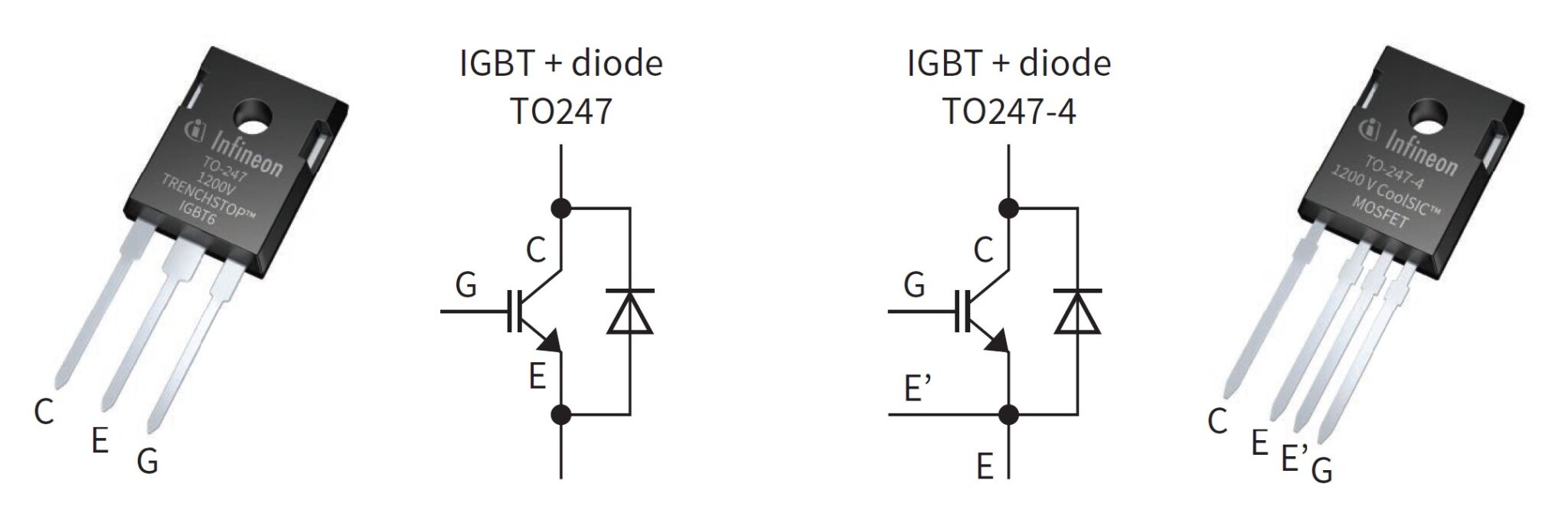

First, a quick introduction to our contenders. An SCR, or Silicon Controlled Rectifier, is like a one-way valve for electricity. Once you trigger it to turn on, it stays on until the current drops below a certain threshold. It's simple, robust, and great for high-voltage, high-current applications where you don't need to switch it off rapidly. An IGBT, or Insulated Gate Bipolar Transistor, on the other hand, is more like a sophisticated electronic switch. You can turn it on and off with a control signal, making it much more versatile for applications requiring precise control and faster switching speeds. They both serve similar overall functions — controlling electrical current — but go about it in drastically different ways.

To continue the analogy from before, SCRs are like reliable old workhorses. They are less fussy, and better when you only have to do a couple things over and over again. For example, you don't want to use an IGBT to do high-voltage DC power transmission.

Conversely, IGBTs are a more modern tool, they can be more complex and are more sensitive. On the other hand, you can use them in more situations.

Key Differences

2. Delving into the Technical Details

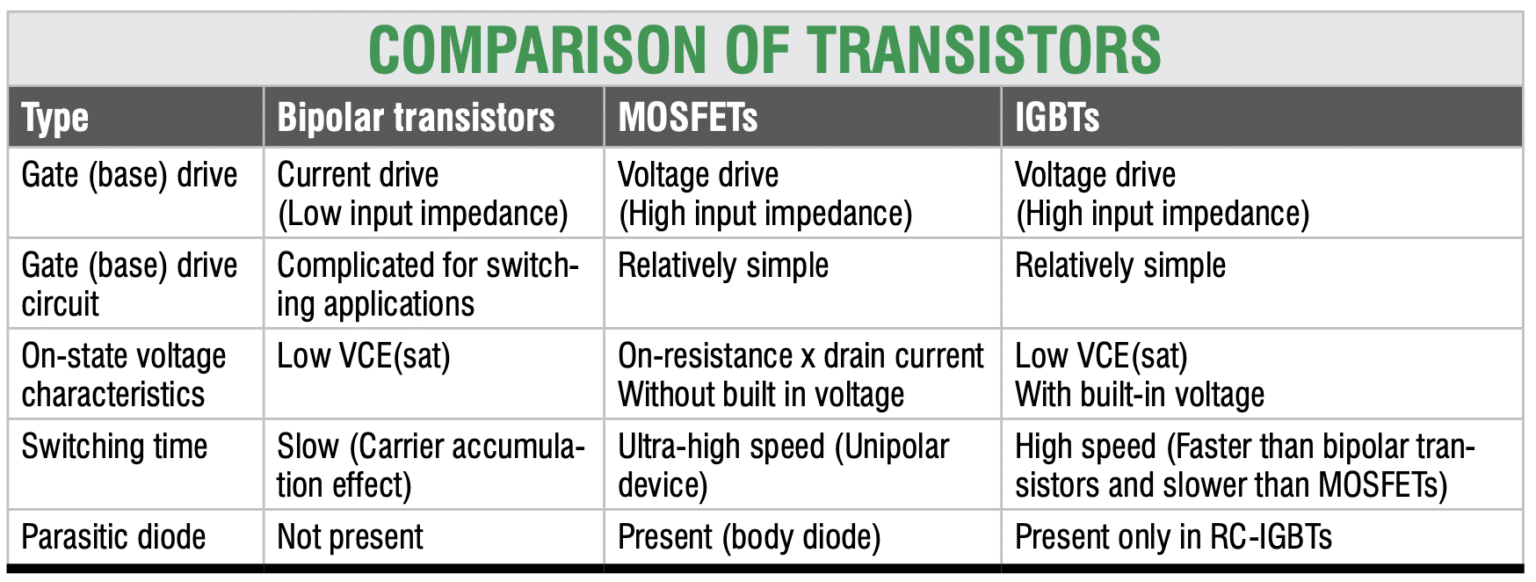

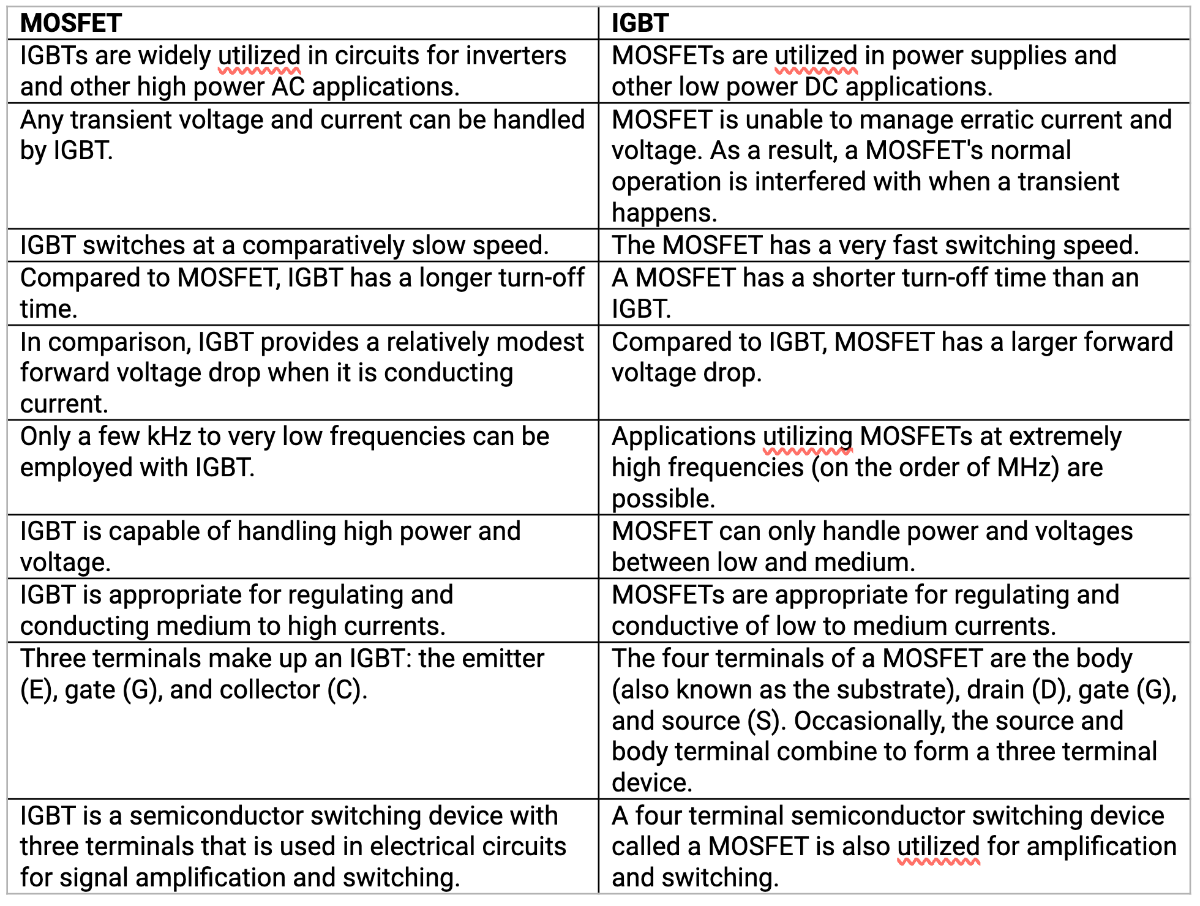

Now, let's dig a little deeper into the nitty-gritty (oops, almost slipped up there!). One of the biggest differences lies in their switching characteristics. SCRs have a relatively slow turn-off time. Once they're conducting, you're pretty much stuck with it until the current naturally drops. IGBTs, however, can be switched on and off much faster — often in microseconds. This speed advantage makes them ideal for applications like variable frequency drives (VFDs) and pulse width modulation (PWM) circuits.

Another crucial factor is the control mechanism. SCRs require a trigger current to turn on, and their state is then dictated by the current flowing through them. IGBTs, on the other hand, are voltage-controlled devices. You apply a voltage to the gate terminal to turn them on and remove the voltage to turn them off. This voltage control makes IGBTs easier to interface with microcontrollers and other control circuitry.

Another notable difference is their voltage and current handling capabilities. SCRs generally excel at handling very high voltages and currents, often surpassing IGBTs in these areas. This makes them suitable for applications like high-voltage DC transmission and high-power rectifiers. IGBTs, while still capable of handling significant power, are typically more limited in their voltage and current ratings compared to SCRs. They also have the benefit of being smaller and lighter.

SCRs typically have larger forward voltage drops compared to IGBTs. While not always a deal breaker, it can result in more power dissipation which is something to be mindful of. IGBTs, on the other hand, can experience a tail current, which is a small current that continues to flow for a short time after the device is turned off. These differences highlight the importance of understanding the specific requirements of your application when making a decision.

MOSFET Vs IGBT Project

Application Scenarios

3. Matching the Right Tool to the Right Task

Okay, enough with the abstract concepts. Let's talk about real-world scenarios. Where does each of these devices truly excel? SCRs are commonly found in applications like high-voltage DC transmission (HVDC), soft starters for motors, and phase-controlled rectifiers. Their ability to handle massive amounts of power and their relatively simple control requirements make them a solid choice for these applications.

IGBTs, on the other hand, are the workhorses of modern power electronics. You'll find them in variable frequency drives (VFDs) for motor control, uninterruptible power supplies (UPS), welding machines, and induction heating systems. Their fast switching speeds and voltage-controlled nature allow for precise control and efficient power conversion. For example, a VFD uses IGBTs to vary the frequency of the voltage applied to a motor, thereby varying the speed. It is critical to ensure the rapid on and off switching required for precise control.

To give you another example, imagine controlling the speed of a large industrial motor. An SCR-based system could be used to gradually ramp up the voltage applied to the motor, providing a "soft start" and reducing stress on the power grid. However, if you need to precisely control the motor's speed and torque in real-time, an IGBT-based VFD would be the far better choice.

When designing any system, you want to keep as few active components as possible. If your system has a need for components that can control current and voltage, consider using IGBTs.

What Is IGBT? Construction And Working Principle Electrical, 40 OFF

Cost Considerations

4. Weighing the Financial Implications

Of course, no discussion of electronic components is complete without considering the cost. Generally speaking, SCRs tend to be less expensive than IGBTs, especially for high-voltage, high-current applications. Their simpler construction and mature technology contribute to their lower price point. However, the overall system cost can be a different story. The simpler control requirements of SCRs can sometimes translate into lower system complexity and reduced costs for control circuitry.

IGBTs, while generally more expensive per device, can offer cost savings in other areas. Their faster switching speeds can lead to smaller and more efficient passive components (like inductors and capacitors), potentially reducing the overall system size and cost. Furthermore, their voltage-controlled nature simplifies the interface with microcontrollers, which can streamline the design process and reduce development time.

The cost of any component should never be the only factor to consider. A good rule of thumb is to select the best component based on your specific needs, and then make adjustments as required to meet cost constraints. In some cases, this might mean using fewer components. It is important to understand the limitations of both types of devices so you can make an informed decision.

Before making a final decision on which one to use, it is always best to compare your estimates on both types of devices. You may find that one device meets the criteria more closely. For example, a system that requires you to switch on and off frequently might not be a good fit for an SCR.

What’s The Difference Between An IGBT And IGCT? Power Electronic Tips

Making the Right Choice

5. Summarizing the Key Takeaways

So, which is better, SCR or IGBT? The answer, as you've probably gathered by now, is a resounding "it depends!" There's no universal winner in this battle of power semiconductors. The ideal choice hinges entirely on the specific requirements of your application.

If you need to control very high voltages and currents and don't require rapid switching, SCRs are likely the better option. If you need precise control, fast switching speeds, and easy integration with control circuitry, IGBTs are the way to go. Consider the trade-offs between cost, performance, and system complexity when making your decision.

Take your time to carefully evaluate your application requirements, weigh the pros and cons of each device, and don't be afraid to consult with experts or explore alternative solutions. Remember, the goal is to choose the device that best meets your needs, not to blindly follow some pre-conceived notion of which is "better."

Ultimately, you may even want to go with a completely different solution. There are new types of components that are constantly being developed in the realm of power electronics. Therefore, be sure to do your research, because you never know when you might be surprised.

How Does An IGBT Work? Meaning & Structure CircuitBread

Frequently Asked Questions (FAQ)

6. Answering Your Burning Questions

Q: Can I use an SCR to replace an IGBT in my circuit?A: Maybe, but probably not without significant circuit modifications. SCRs and IGBTs have different control characteristics and switching speeds, so a direct replacement is unlikely to work. You'd need to carefully consider the implications for your circuit's performance and safety.

Q: Are there any situations where both SCRs and IGBTs are used in the same circuit?A: Yes, there are! In some high-power applications, SCRs are used for initial current control, while IGBTs are used for finer control and switching. This combination can leverage the strengths of both devices.

Q: Which device is more energy efficient?A: It depends on the application and operating conditions. IGBTs generally have lower switching losses at higher frequencies, making them more efficient in applications like VFDs. However, SCRs can be more efficient in applications where they are primarily used for conduction and switching losses are minimal. Again, there is no one size fits all.