Have A Info About Can I Run A 220V Motor On 240V

How To Wire A 110v Motor 220v

Navigating the Voltage Maze

1. Understanding the Voltage Landscape

So, you've got a motor that's stamped with "220V," and your wall socket cheerfully proclaims "240V." The million-dollar question: are we about to witness a spectacular electrical fireworks display, or will everything be just fine? Well, the answer, as with many things in life, is a resounding "it depends!" Let's dive into what those voltage numbers actually mean and what factors come into play.

Think of voltage like water pressure in a pipe. Too much pressure, and things can burst. Not enough, and you're not getting the flow you need. Electrical components, like motors, are designed to operate within a specific voltage range. Going too far outside that range can lead to overheating, reduced performance, or even outright failure. That's why understanding the tolerances is key.

Most electrical equipment isn't designed to be exactly 220V or exactly 240V. There's usually a bit of wiggle room built-in. Manufacturers know that real-world voltage fluctuates. The real question is, how much wiggle room does your motor have? This is usually expressed as a percentage. Checking the nameplate on the motor, often a small sticker, for its rated voltage is the best way to determine if you can use it with 240v.

Now, where do the 220V and 240V standards even come from? Many countries use 220V-240V as their standard household voltage. North America uses 120V, which is why you might see different voltage ratings depending on where the motor was manufactured. It's a historical quirk, really, and something we're stuck with. So always double check to be safe!

The Motor's Nameplate

2. Decoding the Data

Forget consulting a fortune teller — the real key to knowing if your motor can handle the extra voltage is the nameplate. That little metal or plastic tag stuck to the motor is packed with vital information. Don't just glance at the voltage; look for other details like the allowable voltage range, the motor's frequency (Hz), and its power rating (watts or horsepower).

Sometimes, you'll find a voltage range explicitly stated, like "220-240V." If you see that, you're golden! The motor is designed to handle the 240V supply. If it only says "220V," proceed with caution. A little bit of overvoltage might be okay, but too much is a recipe for trouble.

The frequency rating (Hz) is also important. In most places, the standard frequency is either 50 Hz or 60 Hz. Ensure the motor is rated for the frequency of your power supply. Using a motor designed for 50 Hz on a 60 Hz supply (or vice versa) can cause it to run at the wrong speed or overheat. This is especially critical for devices like clocks and timers that rely on the frequency for accurate operation.

Pay attention to the motor's duty cycle. A motor rated for "continuous duty" can run all day without overheating, while one rated for "intermittent duty" needs to rest periodically. Overloading a motor, even within its voltage range, can damage it if you exceed its duty cycle rating. Always follow the manufacturer's recommendations. And if in doubt, it's always best to err on the side of caution.

Assessing the Risk

3. Finding the Safety Threshold

Okay, so the nameplate just says "220V." Now what? A general rule of thumb is that a voltage difference of up to 5% might be acceptable. Anything beyond that, and you're pushing your luck. In this case, 240V is about 9% higher than 220V. That's venturing into potentially risky territory.

However, this 5% "rule" isn't a hard-and-fast law. It depends on the motor's design, its quality, and the actual load you're putting on it. A lightly loaded motor might tolerate the overvoltage better than one working at its maximum capacity. This is more of a guideline, and you have to make your own decisions in the end.

One thing to consider is the type of motor. Induction motors, which are common in many household appliances, are generally more tolerant of voltage fluctuations than synchronous motors, which are often used in precision equipment. Consult a qualified electrician or the motor manufacturer for specific advice.

If you're determined to use the 220V motor on a 240V supply, consider using a step-down transformer. This device converts the 240V supply to a lower voltage, like 220V, providing a safer and more stable power source for your motor. A transformer adds extra cost and complexity, but it's a worthwhile investment to protect your motor from damage.

Mitigation Strategies

4. Solutions for a Smooth Ride

So, you've determined that running your 220V motor directly on 240V is too risky. What are your options? Fortunately, you're not completely out of luck. Several solutions can help you bridge the voltage gap and ensure your motor runs safely and efficiently.

As mentioned earlier, a step-down transformer is a reliable way to reduce the voltage. Choose a transformer with a power rating that exceeds the motor's power consumption to ensure it can handle the load. Connect the transformer between the power supply and the motor, and it will automatically convert the voltage. Check the Amps from the name plate, then find transformer with same amp rating.

Another option is a variable autotransformer, also known as a Variac. This device allows you to adjust the output voltage precisely, giving you more control over the voltage supplied to the motor. However, Variacs are generally more expensive than fixed-ratio transformers, and they may require some technical expertise to set up and use properly.

In some cases, you might be able to rewire the motor to operate on a different voltage. Some motors have multiple windings that can be configured in different ways to accommodate different voltage levels. Consult the motor's wiring diagram or a qualified electrician to determine if this is possible. Keep in mind that rewiring a motor is a complex task that should only be performed by someone with the necessary skills and knowledge.

Finally, consider whether it's worth the risk and hassle. If the motor is relatively inexpensive, it might be more cost-effective to simply buy a new motor that's designed to operate on 240V. This eliminates the need for transformers or rewiring and ensures that the motor is running within its specified voltage range.

The Smart Approach

5. Seeking Expert Advice

Electricity is not something to be trifled with. If you're unsure about any aspect of this process, the safest course of action is to consult a qualified electrician. A professional can assess your specific situation, evaluate the motor's suitability for a 240V supply, and recommend the best course of action.

An electrician can also perform voltage measurements to ensure that the power supply is stable and within the acceptable range. Fluctuations in voltage can damage electrical equipment, even if the voltage is nominally within the specified limits. If the voltage is unstable, an electrician can recommend solutions like voltage regulators or surge protectors.

Trying to save a few dollars by doing it yourself could end up costing you much more in the long run if you damage the motor or, worse, cause an electrical fire. An electrician can help you avoid these costly mistakes and ensure that your electrical system is safe and reliable.

Remember, safety is paramount. When dealing with electricity, it's always better to err on the side of caution. Don't take risks with your safety or the safety of your property. Get professional help when you need it.

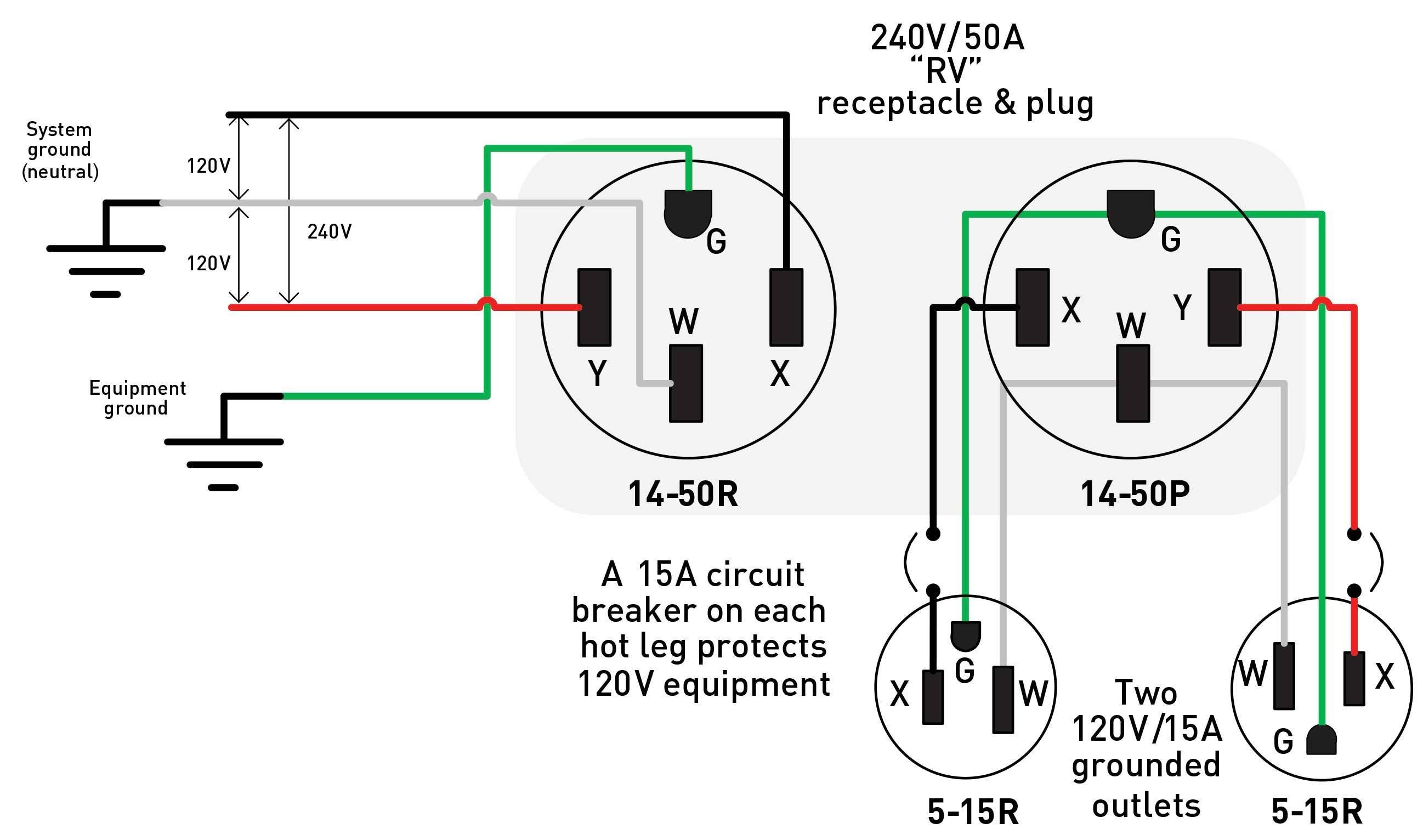

220 Plug Wiring

FAQ

6. Quick Answers to Common Queries

Still got questions swirling around in your head? Let's tackle some frequently asked questions about running 220V motors on 240V power.

Q: What happens if I just plug a 220V motor into a 240V outlet without doing anything?A: It might work for a short time, but you're likely shortening the motor's lifespan and risking damage or failure. It could overheat, run inefficiently, or even burn out. Think of it like forcing a car to run on the wrong type of fuel — it might sputter along for a while, but eventually, something's going to break.

Q: Is it safer to undervolt a motor than to overvolt it?A: Generally, undervolting a motor is less immediately damaging than overvolting it. With undervolting, the motor might struggle to start, run slower, or produce less power. But, consistently running a motor at a lower voltage than it was designed for can lead to overheating due to increased current draw, and also decrease its efficiency. So, both scenarios should be avoided.

Q: Can I use a UPS (Uninterruptible Power Supply) to regulate the voltage?A: Some UPS units have voltage regulation features, which can help stabilize the voltage supplied to your motor. However, not all UPS units offer this functionality, so be sure to check the specifications before purchasing one. A UPS is generally designed to provide backup power during outages, not primarily as a voltage regulator. It's an added bonus if it does regulate voltage, but not its main function.